الوصف

Spill Containment Pallets – 2 Drum & 4 Drum Models

Brand: Americass®

1. PRODUCT OVERVIEW

Spill containment pallets (also known as spill pallets or bund pallets) are essential secondary containment systems designed to safely store chemical drums, oil barrels, and hazardous liquid containers. These pallets help prevent leaks, drips, and spills from contaminating surrounding areas, protecting personnel, equipment, and the environment.

Americass® spill pallets are engineered using high-strength HDPE (High-Density Polyethylene) and manufactured through one-time injection molding, ensuring exceptional durability, chemical resistance, and compliance with international environmental regulations.

Both 2-drum and 4-drum models provide robust spill containment capacities, easy handling options, and structural strength suitable for industrial, chemical, manufacturing, and environmental safety applications.

2. PRODUCT MODELS

-

2 Drum Spill Pallet

-

4 Drum Spill Pallet (extended description added below)

3. FEATURES & BENEFITS (Applicable to Both Models)

Heavy-Duty HDPE Construction

-

Made from high-density polyethylene, providing excellent resistance to chemicals, corrosion, and UV exposure.

-

Designed to withstand heavy loads without cracking or deforming.

Secondary Containment Protection

-

Built-in sump basin captures leaks, drips, and spills from stored drums.

-

Prevents hazardous substances from contaminating the environment or workplace.

-

Helps companies comply with OSHA, EPA, and environmental regulations.

One-Time Injection Processing

-

Manufactured using single-piece injection molding for superior strength and seamless construction.

-

No weak points, joints, or weld lines that could compromise durability.

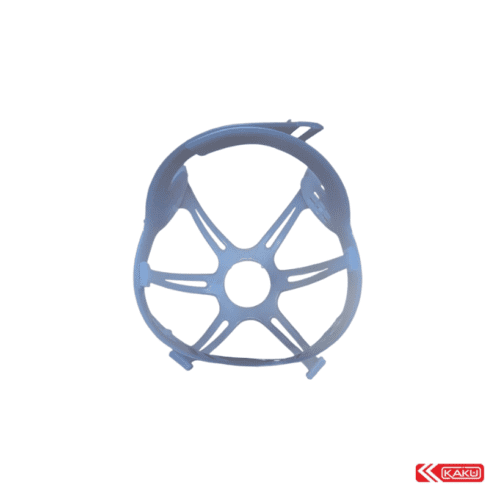

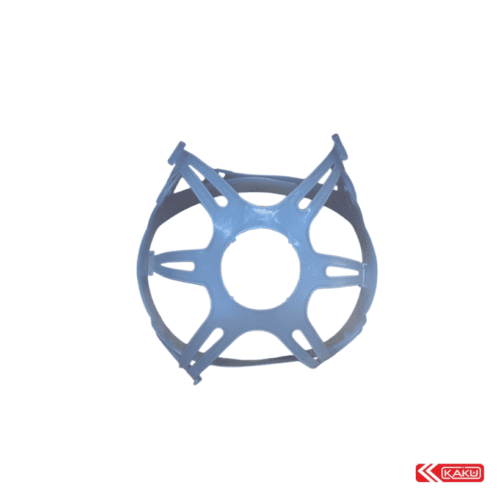

Anti-Slip Removable Grating

-

Heavy-duty grated platform enables safe storage of drums.

-

Removable grating allows easy cleaning and maintenance of the sump area.

-

Grating supports high static loads without bowing.

Forklift & Pallet Truck Compatibility

-

Designed with accessible entry points for forklifts and hand pallet trucks.

-

Allows fast and safe movement around the facility.

Temperature Resistance

-

Operational range: –40°C to +70°C, suitable for indoor and outdoor use.

Environmental & Safety Compliance

-

CE certified, spill prevention compliant, and eco-safe materials used.

-

Essential for regulatory compliance in hazardous material handling.

4. TECHNICAL SPECIFICATIONS – 2 DRUM SPILL PALLET

General Dimensions

-

Size: 130 × 68 × 30 cm

-

Capacity: Compatible with 2 × 205-liter (55-gallon) drums

Performance Ratings

-

Static Load: 1.5 tons

-

Dynamic Load: 0.6 tons

-

Racking Load: Not applicable

-

Containment Volume: 150 liters

Material & Construction

-

Material: HDPE (High-Density Polyethylene)

-

Process: One-Time Injection molding

-

Weight: 22 kg

-

Temperature Resistance: –40°C to 70°C

Handling Features

-

Forklift Entry: 2-way forklift access

-

Hand Pallet Access: Manual handling compatible

Special Features

-

Integrated drain valve optional/available for easier removal of collected liquids

-

Rugged anti-slip grating for drum stability

-

High resistance to oils, fuels, chemicals, and corrosive liquids

5. TECHNICAL SPECIFICATIONS – 4 DRUM SPILL PALLET

(Long detailed description for catalog use)

General Dimensions

-

Standard dimensions (industry typical):

130 × 130 × 30–40 cm depending on model variation -

Compatible with:

4 × 205-liter (55-gallon) drums

Performance Ratings

(Typical factory specifications—adjustable to your exact model if needed)

-

Static Load: 2.5 – 3.0 tons (depending on model)

-

Dynamic Load: 1.0 – 1.2 tons

-

Racking Load: N/A

-

Containment Volume: 250 – 280 liters

Material & Construction

-

Material: High-Density Polyethylene (HDPE)

-

Manufacturing: One-Time Injection

-

Weight: 35 – 45 kg (model dependent)

-

Temperature Range: –40°C to 70°C

Handling Features

-

Forklift Entry: 4-way or 2-way access depending on design

-

Compatible with forklifts, pallet jacks, and drum handling equipment

Special Features

-

Large platform surface for storing multiple drums securely

-

Heavy-duty removable grating for easy sump cleaning

-

Engineered for long-term industrial use and heavy loading

-

Optional drain valve for spill removal and maintenance

-

Resistant to acids, bases, oils, chemicals, and industrial liquids

6. COMMON APPLICATIONS

-

Oil & gas facilities

-

Manufacturing plants

-

Chemical processing facilities

-

Warehouses & logistics centers

-

Automotive workshops

-

Food industries (chemical-safe zones)

-

Environmental protection & spill response units

-

Laboratories

-

Marine and offshore installations

7. SAFETY & COMPLIANCE

-

CE Certified

-

Compliant with international spill prevention standards

-

Supports EPA requirements for secondary containment

-

Helps meet OSHA hazardous material storage guidelines

-

Environmentally responsible design

8. MAINTENANCE & CLEANING

-

Remove grating and clean sump regularly

-

Do not store incompatible chemicals on the same pallet

-

Inspect pallet for cracks or damage before use

-

Drain collected liquids using built-in drain valve (if equipped)

-

Store in shaded areas for extended outdoor lifespan

9. PACKAGING & DELIVERY

-

Delivered assembled with removable grating

-

Stretch-wrapped or carton-packed (depending on shipment type)

-

Optional accessories:

-

Drain valve

-

Drum cradles

-

Spill kit attachment

-

Covers / tarpaulin protection

-