Description

EYE WASH SHOWER GI.The Emergency Safety Shower with Eyewash Station is designed to provide immediate first-aid flushing in the event of exposure to harmful substances in industrial, laboratory, and chemical environments. Constructed from high-quality carbon steel with advanced corrosion resistance, this unit offers durability, precision engineering, and easy maintenance, ensuring long-term reliability in demanding work conditions.

⸻

Material & Technology

• High-Quality Carbon Steel – Strong corrosion resistance and long service life.

• Cold Rolling Process – Improves rust resistance while maintaining durability.

• Advanced Pipe & Valve Technology – High precision, easy to detach, repair, and maintain.

• Sealing Upgrade – “O”-ring seal replaces traditional tape for enhanced safety and reliability.

⸻

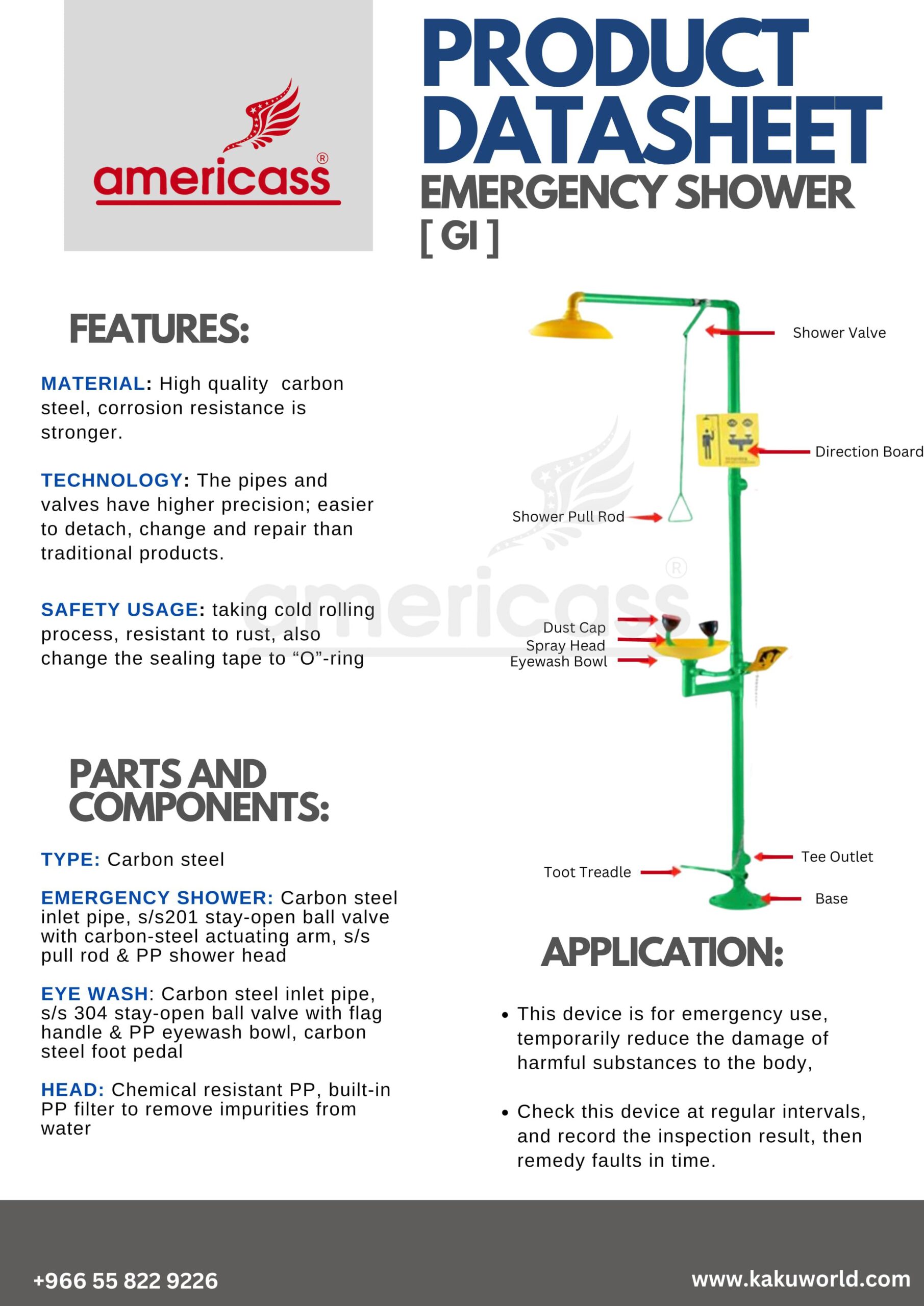

Parts & Components

• Emergency Shower

• Carbon steel inlet pipe

• S/S 201 stay-open ball valve with carbon steel actuating arm

• Stainless steel pull rod

• PP (polypropylene) shower head

• Eyewash Station

• Carbon steel inlet pipe

• S/S 304 stay-open ball valve with flag handle

• PP eyewash bowl

• Carbon steel foot pedal for hands-free activation

• Spray Head

• Chemical-resistant PP construction

• Built-in PP filter to remove impurities from water

• Additional Components

• Direction board for quick identification

• Dust cap for eyewash nozzles

• Base & Tee outlet for secure installation

• Foot treadle for eyewash activation

⸻

Application

• Designed for emergency use to reduce the impact of hazardous chemical spills, splashes, or exposure.

• Suitable for laboratories, factories, warehouses, refineries, and chemical handling facilities.

• Regular Inspection Required – Check the device periodically, record results, and repair faults promptly to ensure safety readiness.

⸻