Description

EYE WASH SHOWER SS.The 304 Stainless Steel Emergency Safety Shower with Eyewash Station is engineered for maximum durability, hygiene, and corrosion resistance, making it ideal for chemical plants, laboratories, marine facilities, and high-humidity environments. Manufactured from standard 304 SUS stainless steel, it ensures superior reliability compared to non-standard grades, while its advanced cold-rolled construction provides long-term resistance against rust and harsh elements.

⸻

Material & Technology

• Standard 304 SUS Stainless Steel – Provides stronger corrosion resistance than non-standard 304 stainless steel.

• Cold Rolling Process – Improves durability and maintains a smooth, sanitary finish without oil or grease.

• Precision Pipe & Valve Technology – Easier to detach, repair, and maintain compared to traditional products.

• Upgraded Safety Sealing – “O”-ring seal design improves leak prevention versus conventional sealing tape.

⸻

Parts & Components

• Emergency Shower

• 304 stainless steel inlet pipe

• Stainless steel stay-open ball valve with actuating arm

• Stainless steel pull rod

• Stainless steel shower head

• Eyewash Station

• 304 stainless steel inlet pipe

• Stainless steel stay-open ball valve with flag handle

• Stainless steel eyewash bowl

• Foot treadle (201 stainless steel) for hands-free activation

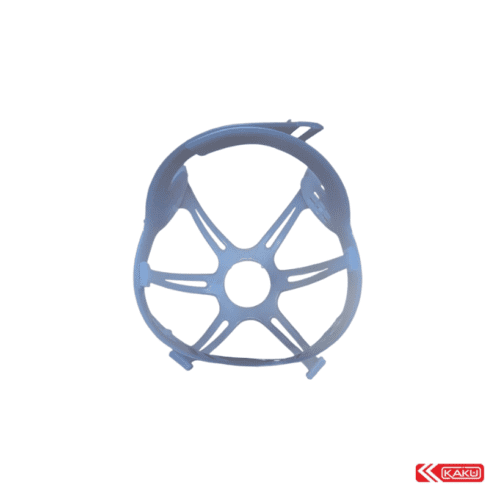

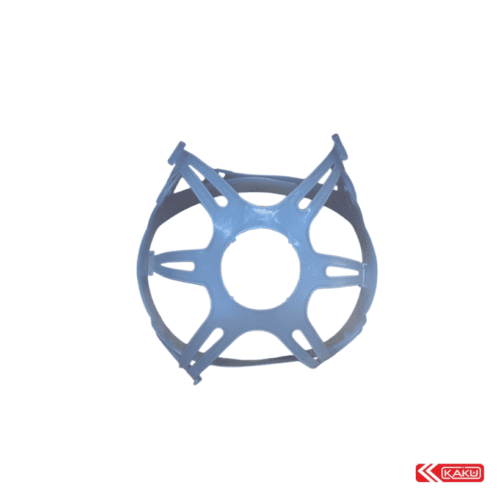

• Spray Head & Filtration

• Chemical-resistant PP spray head

• Built-in stainless steel filter to remove water impurities

• Additional Components

• Direction board for quick identification

• Dust caps for eyewash nozzles

• Tee outlet & stable base for secure installation

⸻

Application

• Provides emergency response for chemical splashes, spills, and exposure to hazardous materials.

• Suitable for laboratories, refineries, pharmaceutical plants, marine facilities, and industrial environments where superior corrosion resistance is required.

• Maintenance Note – Must be checked at regular intervals, with inspection records maintained and any faults remedied promptly.

⸻